Introduction of ColorLink Japan's Technology

ColorLink Japan has optical design and precision processing technologies to provide you with key devices for polarization applications.

-

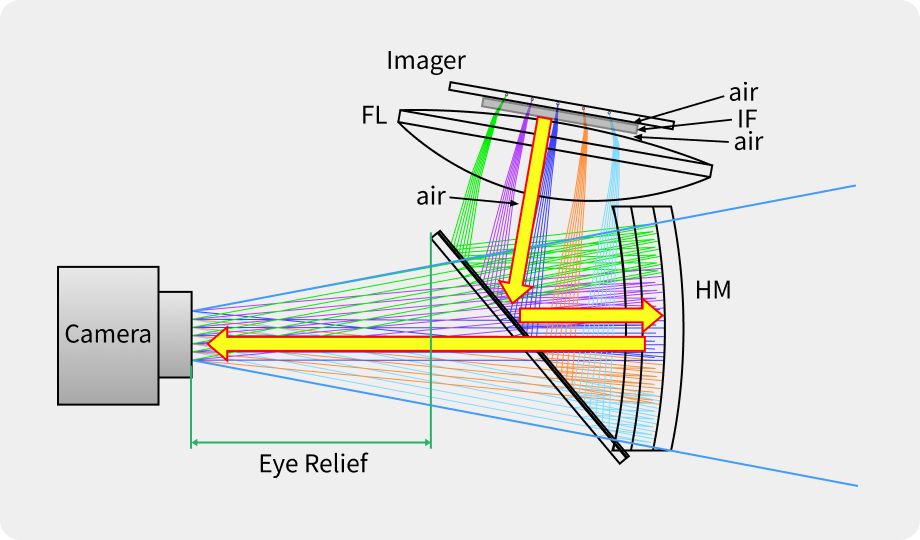

Optical design

- Component designs and optical engine designs with specialized know-how in polarizing optics.

General optical designs

Through the development of the small projector module business, we have acquired a broad range of skills in general optical designs.

Polarizion optical designs

The characteristics of components used in polarization-utilizing equipment may vary depending on the state of polarization.

For any polarization-related issues, please reach out to us – we are the experts in polarization technology. -

Precision manufacturing processes (bondings and assembly)

- Extensive expertise in processing tiny optical components with high precision in a clean room environment.

- Film-to-film welding technology and bonding technologies for different materials such as film and glass.

- Process design and optical module assembly without optical distortion or birefringence.

Optical components processes

Processes may distort materials.Materials distortion can disrupt polarization and degrade product performance. As specialists in polarization, we develop innovations to minimize the effects of polarization.

Bonding

-

Welding

Welding, our core technology, can be considered the very foundation of ColorLink Japan. By eliminating interfacial reflections that occur when combining multiple materials, you can achieve characteristics that cannot be realized by other bonding solutions.

-

Adhesive bonding

Curing shrinkage during adhesive bonding cures disturbs polarization. We have know-how on adhesives and process technologies that minimize curing shrinkage, thereby minimizing polarization disruption.

-

pressure-sensitive adhesives

Pressure-sensitive adhesives are frequently used for bonding various materials; however, their application can sometimes disrupt polarization. At ColorLink Japan, we have the expertise to effectively manage this issue.

Cutting laminated composite material

-

Dicing

We possess advanced dicers utilized in the semiconductor manufacturing process, capable of cutting plate-shaped composite materials with exceptional precision.

-

Slice

With our slicing technology, we can cut composite materials with columnar shapes that cannot be processed using the dicer.

-

Water jet

Our water jet machine quickly cuts plate-shaped composite materials into irregular shapes.

-

Scribe

Scribing, the most popular cutting method for glass sheets, supports cutting irregular shapes.

-

Laser

We possess femtosecond laser cutting equipment, enabling precise cutting with excellent edge quality for films and other materials with irregular shapes.

-

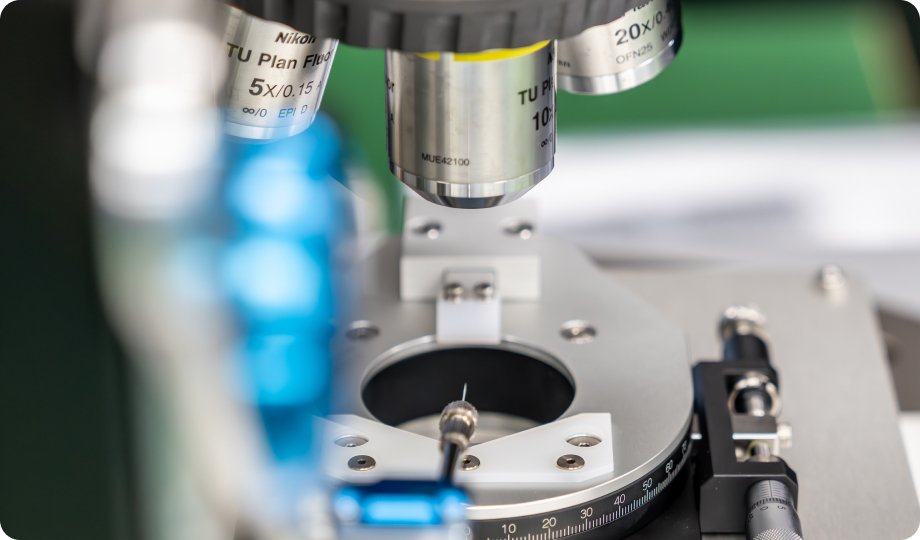

Quality management (ISO 9001 certified)

- Understanding the applications and proactively establishing the optimal quality control methods.

- Appropriate quality control system

Inspections

The products we handle are small-quantity, high-mix, and maybe one-of-a-kind.

One of our areas of expertise is using our unique optical design knowledge to address quality concerns. Additionally, our inspectors, trained as specialists in polarization inspections, will carefully perform the necessary inspections.